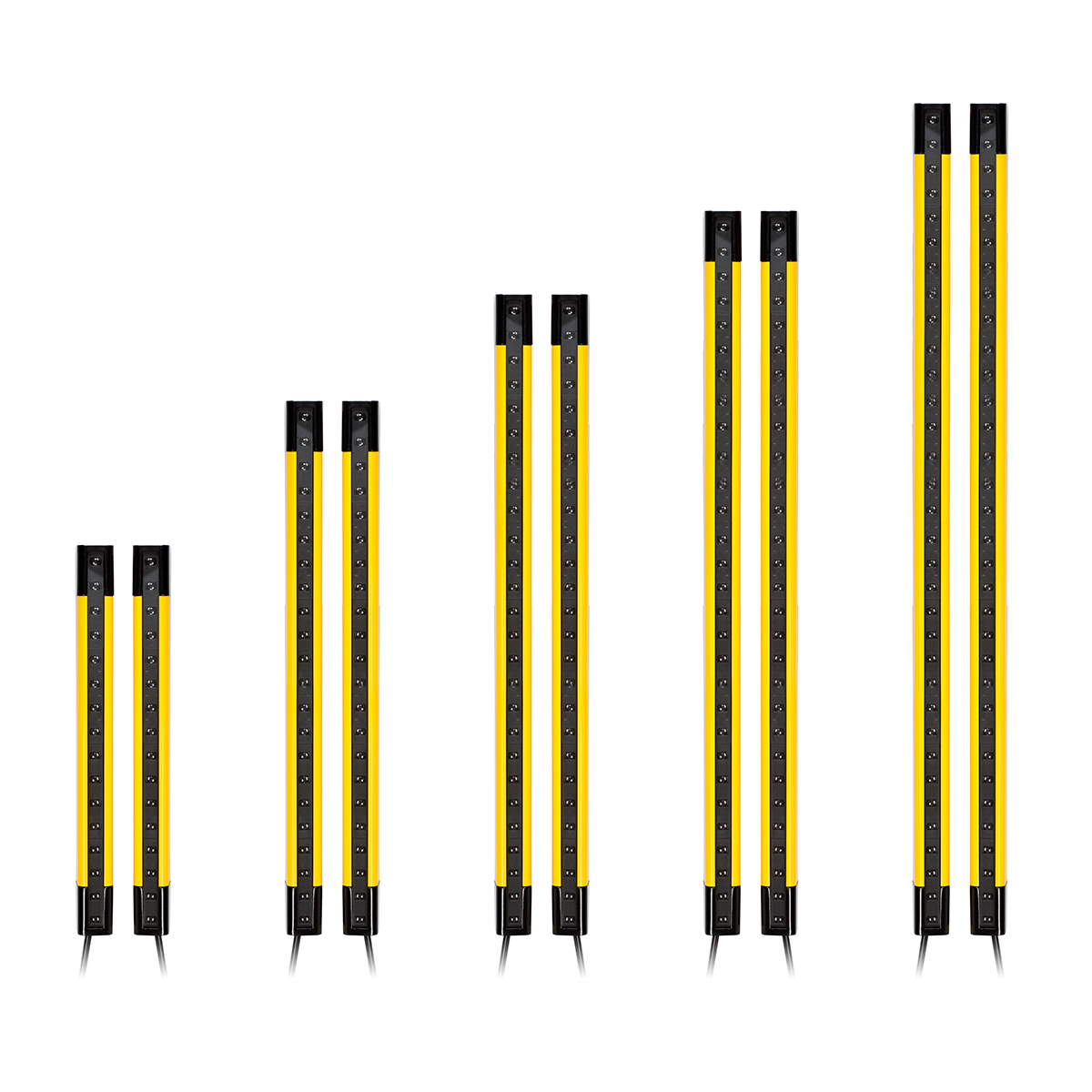

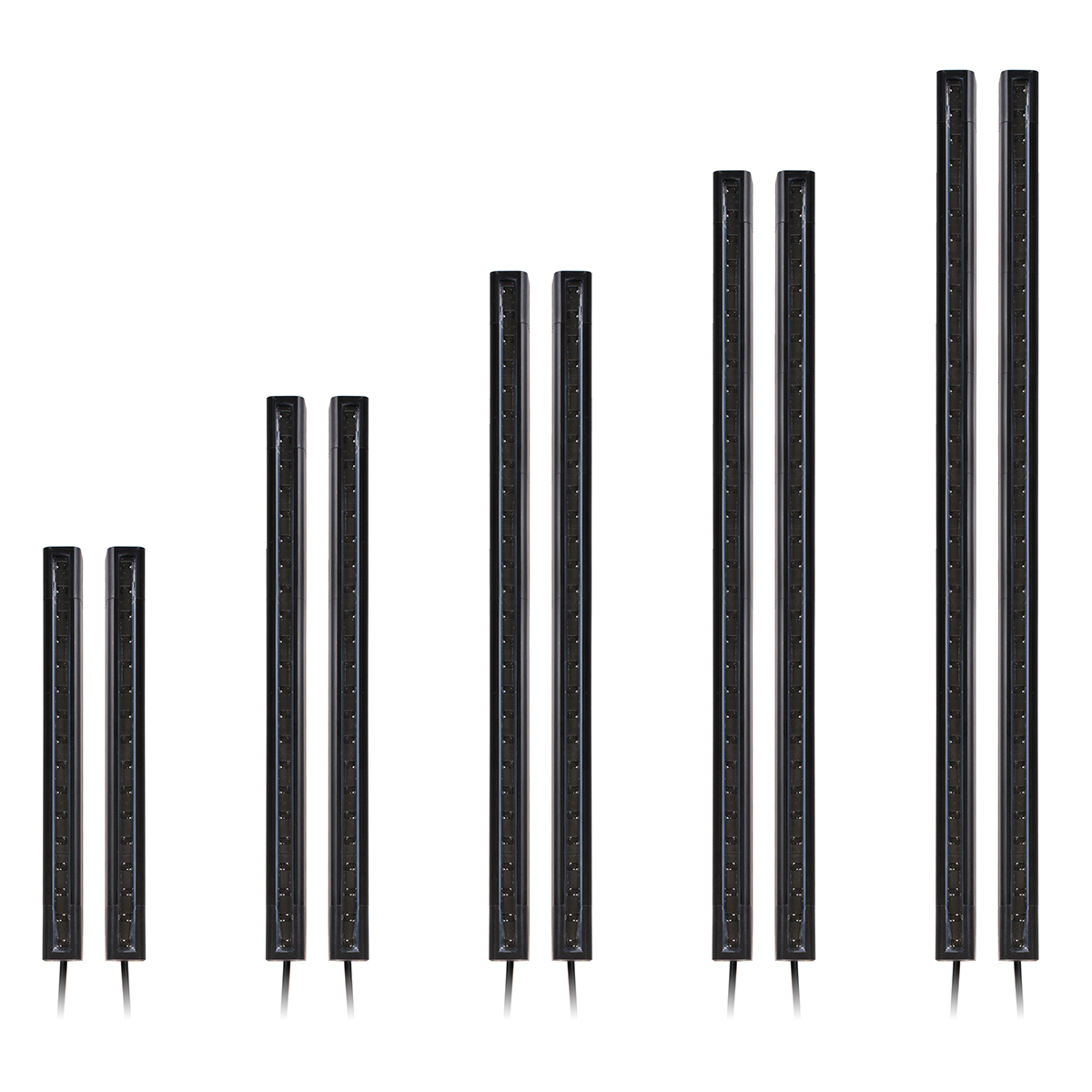

| GSA series safety light curtain | ||||

| Model | GSA10 | GSA20 | GSA40 | GSA80 |

| General parameters : | ||||

| Space between beams | 10mm | 20 mm | 40mm | 80mm |

| Number of optical beams | 32~192 | 16~96 | 08~48 | 08~24 |

| Min detection object | 15 mm | 26 mm | 46 mm | 86 mm |

| Detection distance | 0.5 m ~6m | 0.5 m ~8m | ||

| Light source | 850nm infrared light | |||

| Protection height | 320mm…1,920 mm | |||

| Mechanical and electronic parameters: | ||||

| Supply voltage: | 24v DC ± 20% | |||

| Power consumption | ≤5W | |||

| Power-on delay | 2s | |||

| Working current | Max.300 mA | |||

| Response time | 3ms~52ms(depends on the optical beams quantity) | |||

| Safety output OSSD | 2-ways NPN/PNP Normal close; Short circuit protection, Cross circuit monitoring ;output current< 200mA(30v DC) Switch-on voltage drop :≤1.5v; Cutoff voltage :≤ 1.2V; Load capacitance :30nF; Load inductance :2.2H; Power supply cable resistance :≤ 10Ω; OSSD Test pulse width :200 ~ 300us; OSSD Test pulse period :50 ~ 100ms; | |||

| EDM Selecting input | The input is suspended or connected to low level, the EDM input is invalid and connected to high level, the EDM input is valid; High level: 10 ~ 30V DC, current less than 10mA; Low Level: 0-2V DC | |||

| EDM( External equipment monitoring )input | Through the EDM input terminal, the 24V DC signal from the external equipment contactor can be monitored. High level: 10 ~ 30V DC, current less than 10mA; Low Level: 0-2V DC | |||

| RESET(Reset)input | Manual reset: RESET input terminal is connected to high level through manual switch. Automatic reset: RESET input terminal is connected to high level. High level: 10 ~ 30V DC, current less than 10mA; Low Level: 0-2V DC. | |||

| Indicators | Power(Green )、Fault(Yellow)、Shelter(Red)、Alignment(Blue 3 pieces)。 | |||

| Communication | Optical synchronization | |||

| Protection rate | IP65 | |||

| Work temperature | -25℃~50℃ RH 15~95% | |||

| Connector | M12,6 Pins(Emitter),8 Pins(Receiver) | |||

| Dimension | As per models | |||

GSA

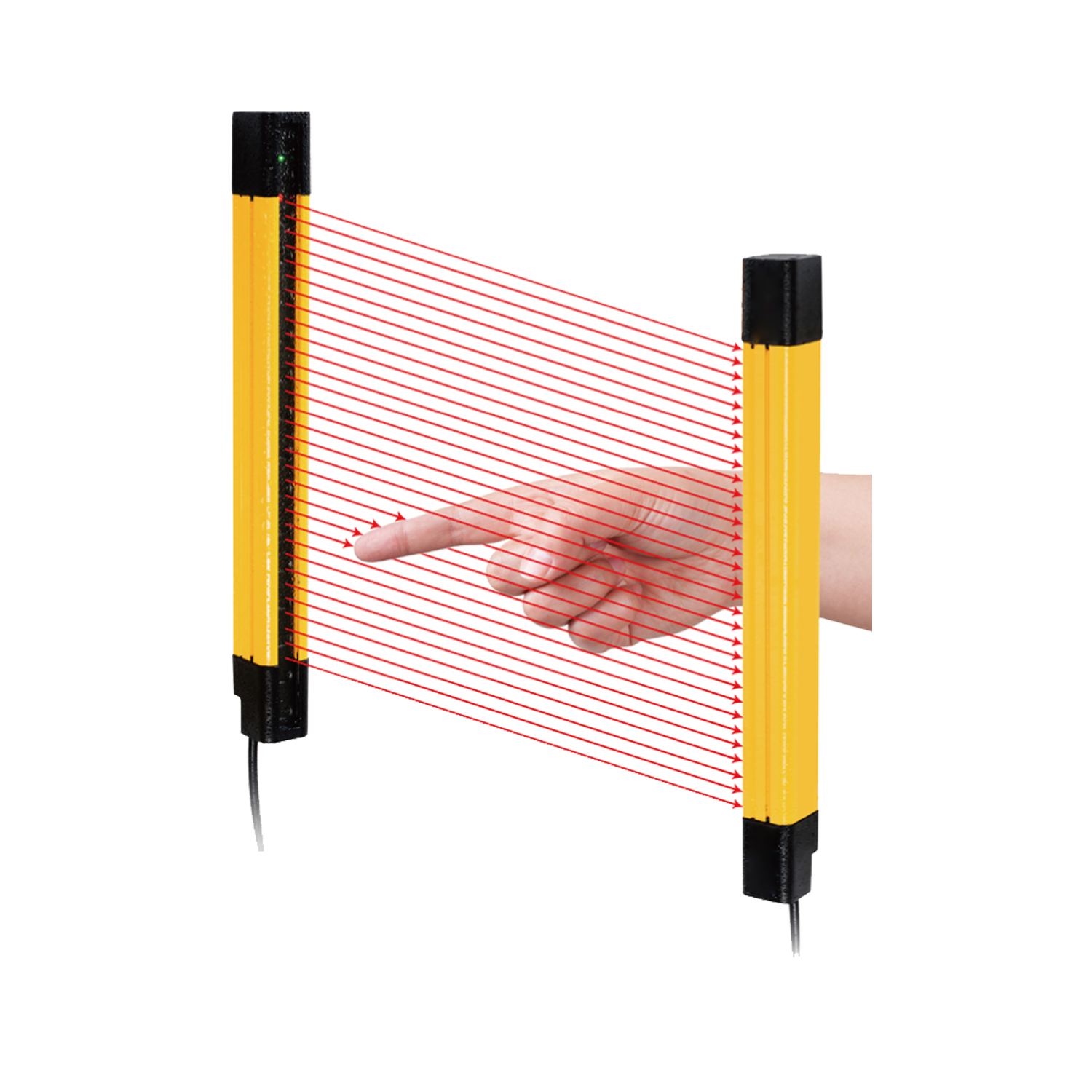

Safety light curtain is also known as photoelectric safety protection device (also known as safety protection device, punch protection device, infrared safety protection device, etc.). In modern factory, people and machines work together, it is easy to cause personal injury to operators. The safety light curtain application on some potentially dangerous mechanical equipment, such as stamping machinery, cutting equipment, metal cutting equipment, automatic assembly line, automatic welding line, mechanical transmission and handling equipment have reduced the occurrence of industrial accidents and protected the life safety of every employee in the production operation.

GSA safety light curtain with Special structure design ensures all-round protection without dead zone; Optical communication easy the electric connection and operation; Self-diagnosis function can check fault module and alarm.

Application fields: mainly used in the machine finishing processing to protect safety of operators, such as:

– Presswork machinery

– Shearing equipment

– Metal cutting equipment

– Automated assembly line

– Automated solder line

– Machinery transmission equipment

– Stereo parking garage

– Rubber, plastic processing machinery.

– Other dangerous regions